Baggage and parcel inspection equipment are essential tools in modern security. They ensure that dangerous or prohibited items do not make their way into secure zones like airports, government facilities, or corporate buildings.

Whether it’s checked luggage at an international airport or a package entering a courthouse, inspection systems, such as X-ray baggage scanners, help security personnel detect threats without the need for manual bag searches.

So, how does this process actually work? Let’s break down the technology, features, and procedures behind baggage and parcel inspection systems.

Why Baggage and Parcel Inspection Systems Are Critical

Modern BPI systems are designed to improve checkpoint efficiency, support real-time threat detection, and comply with international aviation security standards. These systems use dual-view X-ray imaging, automated detection algorithms, and proprietary enhancement software to highlight potential threats for operators in real time.

Whether you’re screening carry-on luggage, parcels, or checked baggage, these systems help security teams detect and isolate threats quickly and effectively with minimal disruption.

Also read: Where to Buy ETDs & Narcotics Detectors in Nigeria | Best Seller

The Core Technology: X-Ray Baggage Scanners

X-ray baggage scanners are part of the most widely used technology for non-invasively inspecting parcels and luggage. They work by using X-rays to penetrate bags, allowing operators to see the contents inside based on how different materials absorb or scatter the radiation.

Step-by-Step: How X-Ray Baggage Scanners Work

- Bag Placement and Scanning

- The user places their bag on a conveyor belt that feeds it into the scanner.

- Inside the scanner, an X-ray tube emits beams through the bag. Denser materials like metal absorb more X-rays and appear darker on the resulting image, while softer materials like clothing or plastic absorb less and appear lighter.

- Detection and Imaging

- Detectors on the opposite side of the bag capture the X-rays that pass through.

- These are converted into digital signals, and specialized software renders an image of the content of the bag on a monitor.

- The resulting image reveals the shape, density, and even material type of the objects inside.

Key Features That Power Modern Scanning Systems

Today’s inspection systems are far more sophisticated than just simple image-rendering machines. Here are some important improvements:

1. Dual-Energy Technology

This method uses two energy levels to differentiate materials by atomic composition. It helps distinguish:

- Metals (e.g., guns or knives)

- Organic materials (e.g., explosives, food)

- Inorganic materials (e.g., plastic containers)

2. Color-Coded Imaging

Modern scanners assign colors to materials:

- Orange = organic

- Blue/green = metals/other inorganic materials

- Black/gray = denser or undefined items

The chart below explains the color schemes based on modern developments.

This visual aid speeds up analysis and helps security personnel spot potential threats more easily.

3. Automatic Threat Detection (ATD)

Using AI and machine learning, some systems automatically flag suspicious objects by comparing scanned items to a database of known threats (like explosives or weapon parts). While the machine assists, a trained human operator still makes the final decision.

Also read: What are High-end Security Services?

The Human Element: Analyzing the Scan

Even the most advanced scanner still relies on the skill of the operator:

- Interpreting the image: Officers look for shapes, density patterns, or placement of objects that could indicate concealed threats.

- Zoom and adjust: Operators can zoom, rotate, or change the contrast of an image to inspect unclear areas.

- Secondary screening: If something is flagged, the item may undergo additional screening such as swabbing, ETD (Explosive Trace Detection), or physical inspection.

Real-World Scenario: X-Ray in Action

Imagine you’re at the airport:

- You place your bag on the belt.

- It enters the X-ray machine.

- The image appears on the security monitor.

- The software flags a bottle-shaped object.

- The officer zooms in and confirms it’s just shampoo—safe to proceed.

That entire process may seem easy, but it’s backed by complex physics, precision engineering, and human judgment.

Why It Matters: The Role of Baggage and Parcel Inspection in Security

X-ray baggage scanners are not just airport tools—they are deployed in embassies, courthouses, correctional facilities, military bases, and private enterprises. Their benefits include:

- Speed and efficiency: Scan large volumes without opening bags.

- Accuracy: Advanced imaging and AI increase detection rates.

- Safety: Reduces need for physical contact and exposure to potential hazards.

- Cost-effectiveness: Minimizes manpower needs while increasing throughput.

In the next section, we will examine some common baggage and parcel inspection equipment, their features, and where to get them in Nigeria.

Common Baggage and Parcel Inspection Equipment, Their Features, and Where to Get Them in Nigeria

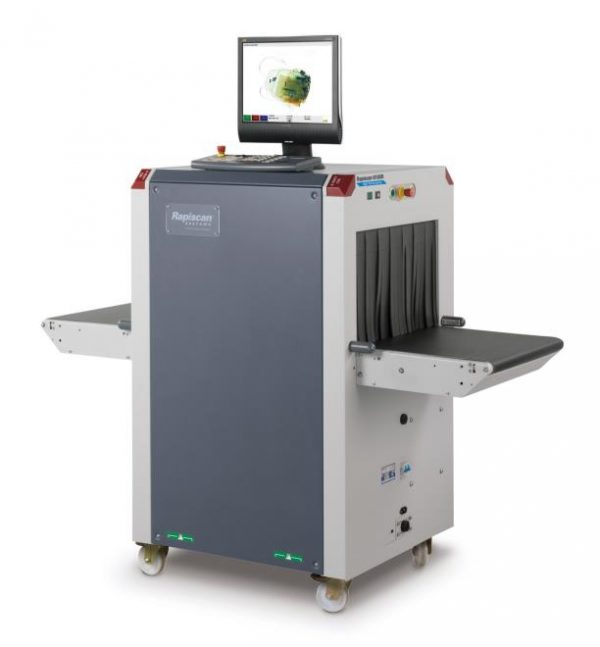

As a Registered Distributor and Technical Service Partner of Rapiscan Systems Limited, Logic Sciences Security Systems Limited supplies, installs, and maintains some of the most advanced Baggage and Parcel Inspection (BPI) equipment available.

Also read: Who is the Best Service Provider of High-End Electronic Security Systems in Nigeria?

In this section, we will explore three state-of-the-art BPI solutions supplied by Logic Sciences and their features. These six BPI systems include:

- Rapiscan Orion 920DX

- RTT 110

- 618XR HP

Each system is designed to meet the toughest regulatory standards while ensuring high throughput, best-in-class image resolution, and superior threat detection capabilities for narcotics, explosives, and contraband.

1. Rapiscan Orion 920DX: High-Performance Dual-View Screening

The Rapiscan Orion 920DX is a dual-view checkpoint screening system with a tunnel size of 640mm x 430mm. Its key capabilities include:

- Detection of explosives and narcotics

- 17 image processing functions for enhanced visual assessment

- Multiplexing and matrixing features for large-scale operations

This system is ideal for airport security checkpoints and other controlled access points where accuracy and speed are paramount. Learn more about the Rapiscan Orion 920DX

2. RTT 110: Fast, High-Throughput Explosives Detection System

The RTT 110 sets the industry standard for automated explosives detection. Capable of screening over 1,800 bags or 2,500 parcels per hour, this system delivers:

- Level 1 decisions in one second

- High-resolution 3D X-ray imaging

- Non-rotating static gantry design for reduced maintenance

Learn more about the RTT 110.

3. 618XR HP: Compact, Portable, and Compliant

For locations requiring mobility and a compact footprint, the 618XR HP offers a 540 mm x 360 mm tunnel and delivers:

- Superior resolution with low-density image enhancement

- Target and NARCScan alerts for real-time threat identification

- Full compliance with EU aviation security regulations

- 14+ image processing tools for accurate contraband detection

This model is especially suited for event venues, embassies, and small checkpoints. Learn more about the 618XR HP.

Refer to our post on baggage and parcel inspection to learn more about other available tools.

Conclusion: How Baggage and Parcel Inspection Systems Protect What Matters

At its core, baggage and parcel inspection is a powerful integration of physics, imaging technology, and human expertise. X-ray scanners serve as a frontline defense in identifying threats—quietly and efficiently screening items before they ever reach secure areas.

By combining features like dual-view imaging, AI-powered threat detection, and advanced material recognition, these systems ensure rapid and accurate decision-making with minimal disruption.

As the need for tighter security grows across airports, embassies, courthouses, and other high-risk environments, the demand for intelligent, scalable screening solutions becomes more critical. Systems like the Rapiscan Orion 920DX, RTT 110, and 618XR HP supplied and maintained by Logic Sciences Security Systems Limited demonstrate how modern inspection technology can keep people safe while meeting international compliance standards.

Whether it’s securing aviation infrastructure or screening parcels at a government facility, these tools aren’t just machines—they’re part of a global effort to protect lives, assets, and national security.

Follow us on X (formerly Twitter) @Logic_sss for access to more security updates.